打開抖音掃一掃

Let's take a look at some exciting moments at the exhibition together!

During the exhibition, Kunshan Zhongneng fully showcased its product advantages and technical capabilities through promotional videos, brochures, and on-site explanations, attracting a continuous stream of visitors from both domestic and foreign markets to visit the exhibition booths and consult face-to-face. Business personnel always maintain a rigorous, serious, and professional attitude when facing questions raised by visiting customers, explaining products carefully, answering customer questions and laying a foundation for good cooperation in the future.

Take a look at our products!

Directly feeding unprocessed materials into the furnace will generate a large amount of smoke and fire, and all dust removal equipment cannot effectively treat them in the long term

We need a device to remove oil and paint from these secondary materials and preheat them before putting them into the furnace

The effect of directly feeding pre treated materials into the furnace

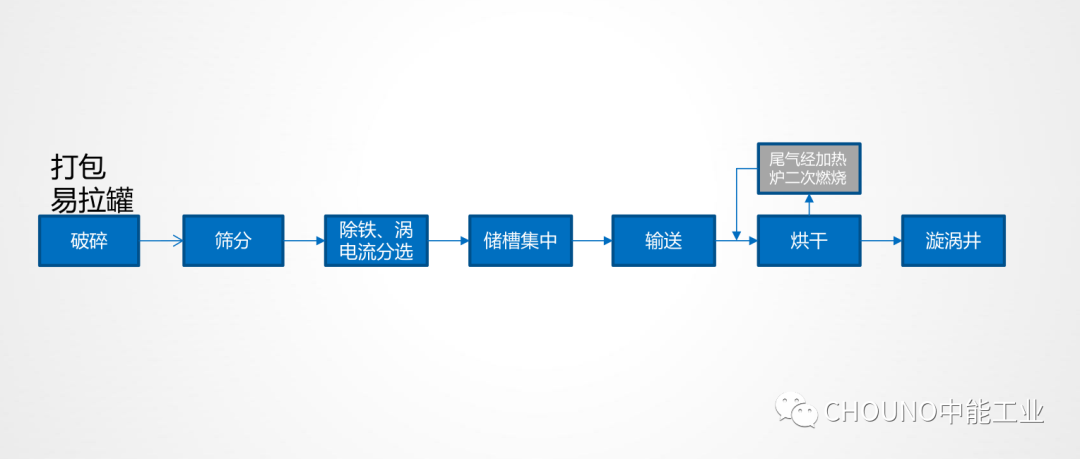

Rear burner paint removal and drying system

What is paint stripping

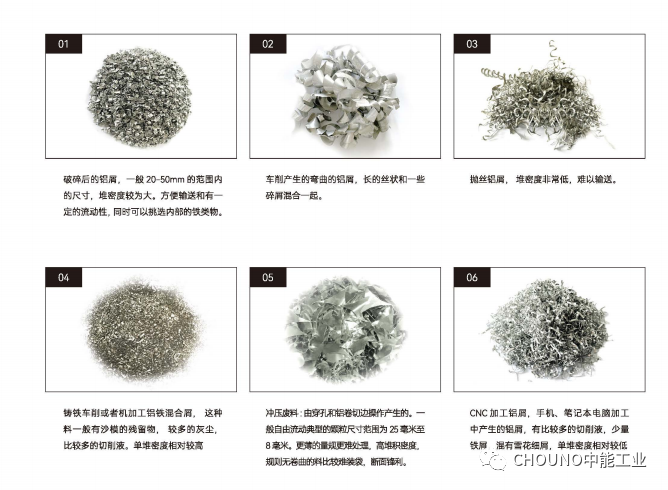

Solution for dehydration and oil removal of aluminum shavings

Dehydration treatment, reducing moisture content to within 2%

Depainting treatment, complete drying of surface cutting fluid and oil stains to reduce burning loss and remove thick smoke

打開抖音掃一掃