打開抖音掃一掃

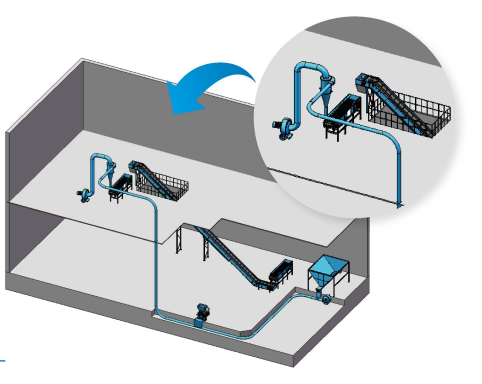

The final stage of any chips treatment system - scrap storage - must be designed to accommodate each current use and potential future demand. Commonly processed aluminum chips are loaded directly into containers, cargo cells or tonnage bales. In some cases, chips may be transported to storage silos or bags, from where they are transferred to the melting furnace. Conventional chips loading systems employ mechanical and pneumatic conveyors as well as various types of fixed or movable chutes. Through the air conveying device, the aluminum scraps can be sent to different silos for storage, the air conveying capacity can reach 6 tons/hour, the maintenance is simple and the cost is low, the conveying distance is more than 360 meters, and the materials can be transported across the workshop, reducing the frequency of forklift truck use.

打開抖音掃一掃